Our MarTECH® loop slurry technology is the number one choice worldwide for HDPE production.

Licensed in 20 countries, resins produced with our PE loop slurry process account for more than 20% of worldwide HDPE. Wherever your resin markets are located, our technology can be your largest single advantage.

MarTECH® Technology

When our breakthrough loop slurry process was formally introduced in 1961, it immediately revolutionized the production of high-density polyethylene. Today we are a world leader in polyethylene production and licensing, with more than 1,000 related patents and more than 80 licensed plants in 20 countries.

MarTECH® Loop Slurry Process

The MarTECH® loop slurry process, licensed by Chevron Phillips Chemical, is the world’s premiere process for the manufacture of high-density polyethylene (HDPE). Meeting customer demands with low costs, high efficiency, and a broad portfolio of polyethylene (PE) products for more than 50 years, the MarTECH® loop slurry process remains one of the most versatile and profitable polyethylene producing processes in the industry.

Continuous Improvement

Our MarTECH® loop slurry technology is the result of relentless focus on innovation. This cutting-edge technology achieves some of the widest product flexibility and largest world-scale facilities. We work directly with licensees to identify opportunities for further technology improvements and cost savings. That is why, year after year, Chevron Phillips Chemical continues to be an industry leader in innovation.

Process

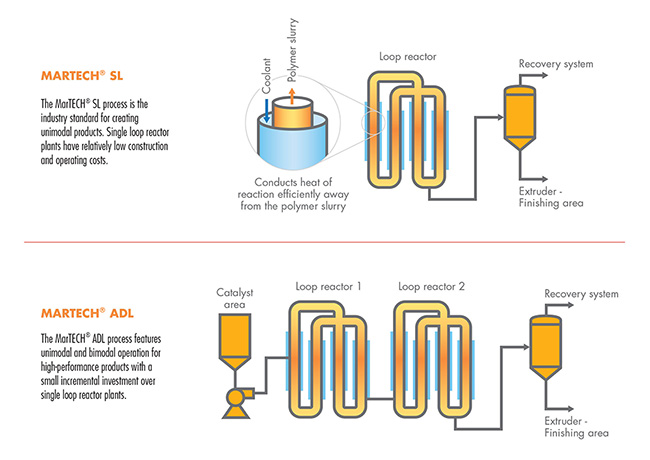

Used in both the Single Loop (SL) and Advanced Dual Loop (ADL) designs, the MarTECH® loop slurry process represents one of the most widely accepted polyethylene production technologies in the industry.

The Unique MarTECH® Loop Slurry Reactor Process

The MarTECH® loop slurry process was formally introduced in 1961 and continues to be the premier loop slurry technology with ongoing research and development. Today, polyethylene is more popular than ever, and the our MarTECH® loop slurry process and world-renowned product quality are the standard by which all other technologies are judged.

Exclusive Licensor of Advanced Dual Loop Technology

We are the exclusive licensor of the Advanced Dual Loop (ADL) technology. This state-of-the-art series reactor technology is a collaboration between Chevron Phillips Chemical and Total Petrochemicals. The ADL technology is capable of producing up to 500 kMTA and incorporates key advancements from modern loop slurry design. The MarTECH® ADL process is capable of producing unique bimodal dual loop products such as PE 100 pipe grades, Extreme Resistance to Crack (XRC) initiation pipe grades, bimodal films and enhanced bimodal blow molding resins, as well as the full product range of MarTECH® technology SL products.

Advantages

Advantages available in our breakthrough MarTECH® loop slurry process today include low-cost world-scale reactor designs, efficient and reliable operations, proprietary catalysts, and one of the widest ranges of polyethylene products. The worldwide reputation and the exceptional resin margins produced by our technology give licensees a global advantage.

Low Capital Costs

Competing technologies require more complicated processes and techniques, increasing the cost to build and operate a facility. The MarTECH® process benefits from a simpler design that allows for fast and less expensive construction, as well as simpler and more reliable operation.

Over the past two decades, a concerted engineering effort has allowed us to reduce process complexity of the plant design. These innovations have helped reduce the capital cost of construction by nearly 50% compared to earlier designs.

Low Operating Costs

The MarTECH® loop slurry process is inherently efficient and reliable compared to alternative technologies due to the simplicity of its design. Efforts to simplify the process flow and reduce rotating equipment have both reduced cost and improved reliability, making the MarTECH® loop slurry process a clear choice for trouble-free operation.

The MarTECH® loop slurry process owes its extraordinary efficiency to three main features:

- High On-Stream Factor: MarTECH® loop slurry process plants have demonstrated on-stream factors of 98% and higher on an annual basis.

- Operational Consistency: The MarTECH® loop slurry process offers efficient reaction heat removal that allows for uniform reactor temperature control within a very tight range. Many competing technologies struggle with non-uniform reactor temperature, which can lead to formation of chunks and product quality variation.

- Quick Product Transitions: The MarTECH® loop slurry process can transition between resins faster than competitive processes due to proprietary catalyst and process designs, with typical transition times as short as three to six hours.

The current generation of loop slurry plants is a cumulative result of more than 50 years of scientific discovery and engineering design. In the past 20 years, Chevron Phillips Chemical scientists and engineers seeking to reduce capital and operating costs have made more than 100 design and mechanical improvements.

Globally Recognized Products/Higher Profitability

The MarTECH® loop slurry process is capable of producing a wide range of polyethylene products, from a variety of catalyst types. Each type of polymer offers specific characteristics and end-use advantages.

Resins made with MarTECH® loop slurry technology are the benchmark for high quality in many industries and often command a premium over competing products. Resins from the MarTECH® process are the overwhelming choice for liquid food containers, household and industrial chemical (HIC) containers, pipe, geomembranes, industrial drums, and many other large-scale applications. Polyethylene resins made from the MarTECH® loop slurry technology account for more than 20% of worldwide HDPE. Due to this wide acceptance, MarTECH® process facilities have enjoyed among the highest margins year after year.

History

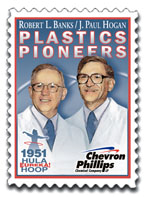

In 1951, research chemists Paul Hogan and Robert Banks were working to improve yields of high-octane gasoline when they discovered two of the world’s most essential plastics — polypropylene and high-density polyethylene. From that initial discovery came the development of the first commercially feasible polymerization process.

Today, Chevron Phillips Chemical research and development teams continue to develop more cost-effective ways to manufacture polyethylene. In the past ten years, the company’s scientists and engineers have implemented more than 100 separate improvements that have led to increased production, improved economy-of-scale due to major increases in the maximum reactor size, and significant decreases in the amount of energy and feedstock consumption required per pound of polymer.

Technical Service

Part of every MarTECH® loop slurry process license is the assurance that Chevron Phillips Chemical is there every step of the way to promote safe, reliable and efficient operations.

Support for New Licensees

A new MarTECH® licensee will begin the journey with a tailored process design package prepared by expert scientists and engineers to meet the licensee specifications. Additionally, the technical manual detailing more than 50 years of research and development helps to bring the licensee up to speed with the technology. Process experts support all stages of design and engineering.

We provide operations and product training to licensee representatives, passing on generations of technical, operating and product experience. During the construction phase, our experts conduct a plant inspection to help identify and resolve issues. During the commissioning and start-up phase, our team is on site supporting the licensee to achieve a safe and successful start up.

Polyethylene Information Exchange Program

Licensees have greatly valued and actively participated in the Chevron Phillips Chemical Polyethylene Information Exchange program. This program provides an opportunity for licensees to learn the latest commercial developments and technological improvements available in the MarTECH® loop slurry process. Every two years, we host an Information Exchange Meeting (IEM) where active licensees and Chevron Phillips Chemical manufacturing, research and technology personnel gather to discuss and share the latest commercial developments and technological improvements. A typical IEM has more than 100 participants and vendors.

Other benefits of participating in the Information Exchange Program include:

- Access to Chevron Phillips Chemical subject matter experts through ongoing correspondence and onsite support as needed

- Improved operations through open sharing of best practices

- Process improvement reports developed by Chevron Phillips Chemical and other licensees that are applicable to existing plants

- The latest product improvements, which allow licensees to improve margins through enhanced physical properties and better processing

- Access to commercially new and exciting products

MarTECH® process licensees have the industry’s most advanced technology when building a MarTECH® technology loop slurry facility. With the Information Exchange Program, they are able to stay at the leading edge of technology for the future.

Getting Started

We continue to evaluate new licensees and partners on a selective basis. Strategic licensing decisions are made based on geographic and company-specific information.