ForSField™ G-121 protective coating is a high-performance, two-part protective coating designed to provide superior protection for steel or concrete structures in corrosive environments. It has excellent adhesion to metal, concrete, and galvanized metal. G-121 can be used as a primer, tie coat, top coat, and for chemical immersion service. It is available in gray.

Features

- Free of VOCs, HAPs, and solvents

- Color – gray

- Self priming and surface tolerant

- Exceptional resistance to acids, bases, and chemicals

- Excellent adhesion to steel, galvanized steel, and concrete substrates

- Extended pot life

- Long overcoat interval

Dry Film Thickness and Coverage

- 6-10 mils (+/- 1 mil) DFT recommended for atmospheric service

- 12-20 mils (+/- 2 mils) DFT (two coats) recommended for immersion service

- Up to 10 mils maximum per coat (to prevent sagging)

- Theoretical coverage of 160 ft2/gal @ 10 mils

- Theoretical coverage of 80 ft2/gal @ 20 mils

Intended Uses

For use as a medium-build epoxy coating to enhance corrosion and chemical resistance in a range of environments including petrochemical plants, mining facilities, pulp and paper mills, chemical process plants, and offshore structures. G-121 can be used as a primer, mid-coat or unicoat. It can be used over tightly adhering rust to stabilize it and slow further corrosion. This coating is suitable for both maintenance and new construction applications.

Surface Preparation

ForSField™ G-121 protective coating is a surface tolerant coating so it is able to maximize adhesion to substrates that are not perfectly prepared and helps stabilize existing rust. Since this coating shows excellent adhesion to tightly adhering rust it can be used under these non-ideal conditions. A lower degree of surface preparation will affect adhesion to the surface. The surface to be coated should be clean and dry. Utilize sufficient methods to eliminate excess debris, scale, rust, water, or oil that may interfere with coating adhesion. It is recommended to clean all metal surfaces by solvent wiping with methyl ethyl ketone (MEK), acetone or a hydrocarbon solvent such as mineral spirits before coating or surface profiling. Coating performance may also be improved by use of a soluble salt removal package and thorough drying of the surface before coating. For best results, the following surface preparation is recommended.

Concrete

Concrete surfaces should be fully cured, cleaned and degreased. For optimal adhesion performance, acid etching is recommended by using muriatic acid or a similar product.

Steel

For optimal results, prepare the surface in accordance with SSPC-SP 5 / NACE 1 / Sa. 3 / BS4232 First Quality / 31 GP 404 Type 1 / JASh3 or JASd3, white metal blast cleaning for atmospheric and immersion service. An anchor profile of 2-3 mils is recommended.

As an alternative, prepare the surface in accordance with SSPC-SP 6 / NACE 3 / Sa. 2 / BS4232 Third Quality / 31 GP 404 Type 2 / JASh 1 or JASd 1, commercial blast cleaning for atmospheric service. A minimum anchor profile of 1.5 mils is recommended.

Can be applied over galvanized steel after surface preparation in accordance to SSPC-SP 1 solvent cleaning. For highly aged galvanized surfaces, light abrasion with very fine grit sandpaper prior to solvent cleaning is preferred.

Previously Painted Surfaces

ForSField™ G-121 protective coating can be applied over most coatings in sound condition but compatibility should be tested in advance. Sanding or abrasion to roughen and de-gloss the surface is recommended, then solvent wipe the surface. Ensure the surface is dry and free from excess dust or debris before applying the fresh G-121 coating.

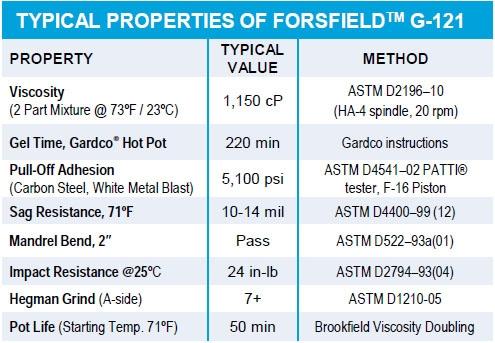

Performance Data

All of the data presented are reported from tests performed on coatings applied under controlled laboratory conditions and may not represent exact values achieved in field applications.

Application

Listed below are general guidelines for the application of ForSField™ G-121.Specific project conditions may require modifications to theseguidelines to achieve the desired results. Ensure the ambient temperature, unmixed product components and surface to be coated are above 50°F (10°C). Both components should be no warmer than 100°F (38°C) at the time of mixing or application, due to rapid reduction in working time with increasing temperature. Best results are achieved with a relative humidity of 60% or less and a surface temperature of at least 5°F (3°C) above the dew point.

Application by Brush, Roller

A clean napless (phenolic core) roller or disposable paint brush is recommended. A small spatula or putty knife can be used to shape the surface and knock down thick areas immediately after brushing. Work coating into all corners, edges, complex areas and irregularities. After curing 30 minutes, lightly brush out any sags, drips, or thick areas. Multiple coats may be required to achieve desired appearance and the desired dry film thickness.

Mixing and Spray Application

Material is supplied in two containers as a 0.7-gallon unit. It is strongly recommended to mix a complete unit. Once the unit has been mixed it should be applied to the desired surface within the pot life specified below. The coating components are packaged with the correct ratio of Part A (resin) to Part B (hardener). Therefore, combine the contents of the epoxy resin (Part A) and hardener (Part B) cans by pouring the quart can of hardener (Part B) into the partially full gallon can of epoxy resin (Part A). Mix thoroughly with a power agitator, such as a Jiffy® Mixer HS-1, HS-2, or HS-3 and 800 rpm electric drill for 5 minutes. Once the unit has been mixed, start applying the coating using a brush or napless roller. Use the material within the pot life specified below, then allow the unused portion to cure in the can and mix a new unit for further coating work.

- Thinning is not recommended; coating too thick to brush is past its usable pot life.

- The mix ratio by weight is 2.91 lbs of Part A to 1.0 lb of Part B

- The mix ratio by volume is 0.46 gal of Part A to 0.24 gal of Part B

- Recommended clean-up solvent is MEK or acetone

- Pot life – approx. 1 hour at 75 °F (24 °C)

HEAT WARNING! Curing epoxy coatings generates significant heat. Never hand mix the ForSField™ G-121R epoxy resin with the ForSField™ G-121H hardener in combined quantities larger than 1 gallon at a time. Doing so will generate significant heat and the combined materials may, if not used promptly, reach temperatures which can cause severe burns to skin (potentially as much as 300°F or higher). Do not mix the epoxy resin with the hardener in containers made of materials such as foam or glass. If a container of mixed epoxy resin and hardener starts to exotherm (heat up rapidly), take precautions to move the container to a location outdoors or with good ventilation, away from other materials, and stay back until it finishes curing and cools down.For industrial/commercial use only. Application must be performed by trained personnel only.

Top-Coating

- Can be top-coated; compatibility of a specific product should be pre-tested

- Allow 72 hours after applying final coat of G-121, before top-coating with a different coating

- If the G-121 coating is aged more than a week, dust and other contaminants may have collected at the surface; clean and solvent-wipe the surface with before applying the top-coat

Shelf Life Information

ForSField™ G-121 should be stored in an air-conditioned environment, no warmer than 100°F (38°C). The shelf life of ForSField™ G-121R epoxy resin and G-121H hardener is 2 years in the original unopened containers.

Packaging

ForSField™ G-121 Protective Coating is available in boxed 1.4- gallon kits containing two coating units:

- Shipping net weight (kit) approximately 15.3 lb (6.9 Kg)

- Part A (epoxy resin, density = 12.25 lb/gal) in two 1-galloncontainers each containing 5.7 lbs (2.6 kg, 0.46 gal) of epoxyresin (partially full)

- Part B (hardener, density = 8.175 lb/gal) in two 1-quartcontainers each containing 2.0 lbs (0.89 kg, 0.24 gal) ofhardener