ForSField™ TZ-904 protective coating is a polysulfide-modified novolac epoxy coating which features zero VOC, high-build capability, and is engineered to provide outstanding protection for steel structures in corrosive marine environments. It can be easily applied to both flat surfaces and edges with excellent performance and durability. Its fast cure time, excellent adhesion, improved flexibility, ability to be applied in hot or cold weather, and outstanding film build makes ForSField™ TZ-904 protective coating the right solution for your toughest marine splash zone applications.

Features

- Free of VOCs, HAPs and solvents

- Convenient 1:1 volumetric mix ratio

- Bio-content is 27% by weight

- Typical gloss range of 60-70% @ 600

- Self priming and surface tolerant

- Excellent adhesion to prepared steel

- Excellent abrasion and impact resistant

- Excellent corrosion and cathodic disbondment resistance

Dry Film Thickness and Coverage

- 90 mils (+/- 10 mils) dry film thickness (DFT) recommended

- 125 mils DFT maximum

- 60 mils maximum per pass (to prevent sagging)

- Theoretical Coverage of 18 ft2/gal @ 90 mils

Intended Uses

The ForSField™ TZ-904 protective coating is intended for the protection of steel structures in highly corrosive environments such as marine splash zones as well as other immersion service. It can be applied as a single high-build film over new metal surfaces or over most coatings in sound condition. It can be used over tightly adhering rust to encapsulate it and prevent further corrosion. This coating is suitable for both new construction and maintenance applications when a full white metal blast surface preparation might not be possible or feasible.

Surface Preparation

ForSField™ TZ-904 protective coating is a surface tolerant coating so it is able to maximize adhesion to substrates that are not perfectly prepared and encapsulates existing rust. A lower degree of surface preparation may adversely affect adhesion to the surface. The surface to be coated should be clean and dry. Utilize sufficient methods to eliminate excess debris, scale, rust, water, or oil that may interfere with coating adhesion. It is recommended to wipe clean all metal surfaces with a hydrocarbon solvent such as methyl ethyl ketone (MEK) after surface preparation and before coating application. For best results, the following surface preparation is recommended.

Primers

The product is self-priming, so a separate primer is not required unless specfied in the project.

Steel

For optimal results, thoroughly prepare 100% of the surface in accorande with SSPC-SP5 / NACE1 / Sa. 3 / BS4232 First Quality / 31 GP 404 Type 1 / JASh3 or JASd3, White Metal Blast Cleaning for atmospheric, immersion, or splash zone service. An anchor profile of 3-4 mils is recommended.

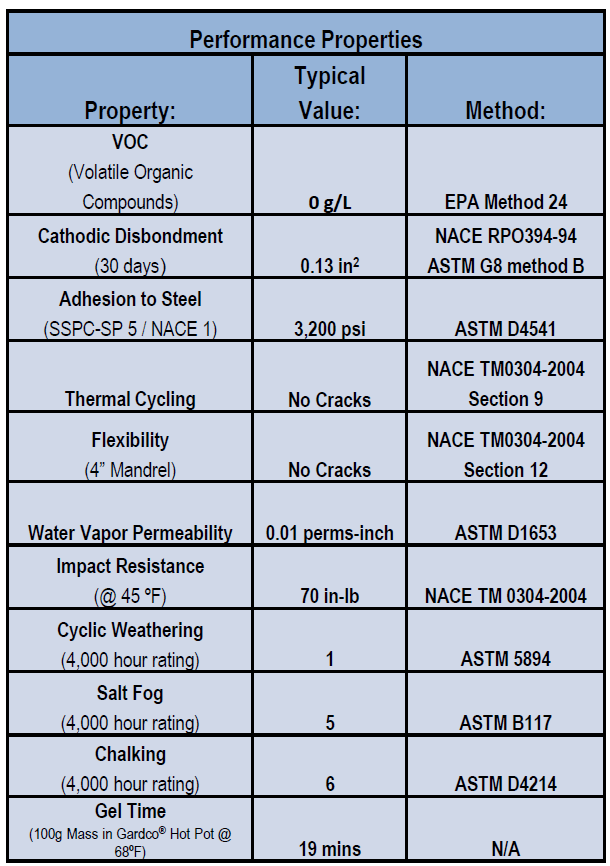

Performance Data

All of the data presented in this technical data sheet are reported from tests performed on coatings applied under controlled laboratory conditions and may not represent exact data achieved in field applications.

Application

Listed below are general guidelines for the application of this product. Specific job site conditions may require modifications to these guidelines to achieve the desired results. Heating of the components up to 130oF will make it easier to handle and transfer from the original containers. Best results are achieved with a relative humidity of 60% or less and a surface temperature of at least 5oF (3oC) above the dew point.

Mixing and Spray Application

- Mix ratio is 1:1 by volume

- Thinning is not recommended

- Plural component airless spray equipment capable of heating coating to 170oF and provide in line pressures of 4,700 psi at the tip

- Re-use of TZ-904H hardener is not recommended and opened partial containers should be discarded

- Recommended clean up solvent is MEK or acetone

HEAT WARNING!

Curing epoxy generates significant heat. Never hand mix the ForSField™ TZ-904R epoxy resin with the ForSField™ TZ-904H hardener. Doing so will generate significant heat and the combined materials may reach temperatures which can cause severe burns to skin, melt plastic and foam, and ignite combustible materials (potentially as much as 300oF or higher). Do not mix the epoxy resin with the hardener in containers made of materials such as plastic, foam or glass. If a container of mixed epoxy resin and hardener starts to exotherm (heat up), take precautions to move the container to a safe location.

For industrial/commercial use. Application must be performed by trained personnel only using an appropriate plural component sprayer.

Top-Coats

- Can be top-coated but compatibility would need to be tested beforehand

- Allow 4 hours after applying final coat, before top-coating with other coatings

- If coating is older than five days, clean surface before top-coating

Shelf Life Information

- We recommend storage at a controlled temperature of 25oC.

- Shelf life for ForSField™ TZ-904R Resin is 1 year in original unopened container.

- Shelf life for ForSField™ TZ-904H Hardener is 3 years in original unopened container.

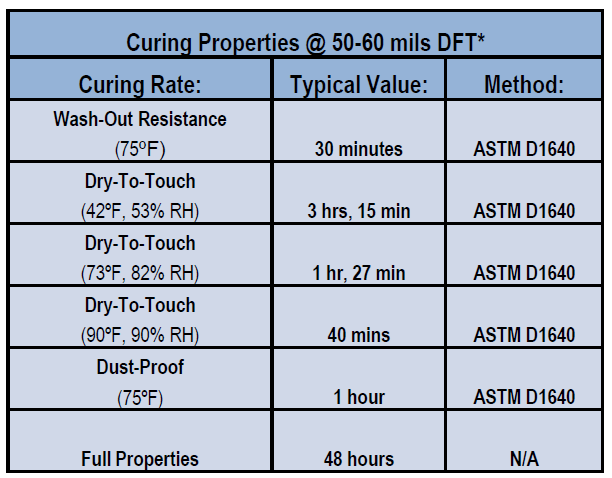

Curing Schedule

Packaging

- The ForSField™ TZ-904 protective coating is available in pail (4 gallons), and drums (50 gallons).

Product Density

- Density for the ForSField™ TZ-904R Resin is 11.60 lbs/gal.

- Density for the ForSField™ TZ-904H Hardener is 8.30 lbs/gal.

Product Safety Information

- Material Safety Data Sheets are available upon request and may also be found here.