PlatinumStripe® 1800 Series PE-RT Pipe

High-density polyethylene (HDPE) PE4710 pipes manufactured for pressurized applications in the United States typically have a maximum allowable operating temperature of 140°F. PlatinumStripe® 1800 Series Polyethylene – Raised Temperature (PE-RT) Pipe significantly expands the operating window for polyethylene (PE) pipes to be used in pressurized applications, with allowable operating temperatures as high as 180°F (82°C). Its higher temperature allowance, coupled with its excellent oxidative resistance and stress cracking resistance, makes it an ideal choice for high-temperature industrial, mining, and oil and gas gathering applications.

For more information, see the PlatinumStripe® 1800 PE-RT Pipe product page.

DriscoPlex® 4800 Series PE Pipe

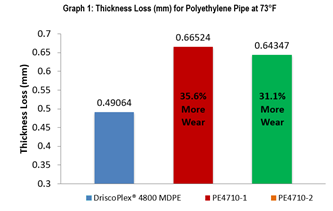

PE4710 pipes are a frequent choice for transporting slurry solutions. Two characteristics that have been shown to improve abrasion resistance in plastics are increased side branching, when short polymer chains randomly bond to the main polymer chain, and decreased hardness. DriscoPlex® 4800 Series PE Pipe has more side branching and is softer than PE4710 pipe materials. ASTM G75 sand slurry abrasion testing results show that DriscoPlex® 4800 Series PE Pipe offers a significant improvement in abrasion resistance over PE4710 alternatives.

For more information, see the DriscoPlex® 4800 Series PE Pipe product page and PP844-TN Slurry Abrasion Resistance of PE Pipe, found on the resources page.

PolarPipe® White-Shell PE Pipe

When exposed to direct sunlight, black PE pipe in above-grade applications can reach temperatures far above ambient. Higher pipe temperatures correspond to higher rates of thermal expansion and greater reductions of the allowable operating pressure of the pipe. Performance Pipe’s PolarPipe® White-Shell PE Pipe has a co-extruded white PE shell that minimizes PE pipe’s absorption of radiant heat, thus reducing the temperature of the pipe in above-grade applications. Lower pipe temperatures reduce thermal expansion of the pipe and conserve the pipe’s allowable operating pressure rating.

For more information, see the PolarPipe® White-Shell PE Pipe product page.

Plexco® Instube®5 2600 Series Flame Retardant Polyethylene Tubing

Plexco® Instube® Flame Retardant Polyethylene Tubing products have been a widely used tubing for pneumatic instrument controls for decades. The latest innovations in this product line have expanded its uses to new applications. Our new extrusion line is capable of producing Plexco® Instube®5 2600 Series Flame Retardant Polyethylene Tubing at higher production rates with tighter manufacturing tolerances than ever before.

For more information, see the Plexco® Instube®5 2600 Series Flame Retardant Polyethylene Tubing product page.